How We Build Your Home

Day One

After your block is cleared and leveled, we get straight into it. Standard precast footing pads are placed according to the precast wall panel layout. No form work or mess here and we’re ready for tomorrow’s wall delivery

Day Two

Your home arrives on trucks. All of the panels have been precast at the factory to our engineered specifications. The window openings and their sills, the lintels for both doors and windows are all done. These solid precast concrete wall panels are the structural load-bearing elements of your home. Our unique system comes complete with standardised connections that provide the structural integrity.

Each panel is lifted into place on top of the footing pads. It is then plumbed, squared, temporarily braced where needed and fastened into place with our patented bracketing system. At the end of day two the home is square plumb and true and will stay that way. Now we’re ready for the roof.

Days 3 and 4

A top plate is fastened to the external walls using our bracketing system and the roof trusses are fixed to it. Then the roof is completed making the whole inside area a dry zone for the remainder of the project. Notice that the pre-cast concrete walls are the load bearing elements. On a brick-veneer home, the bricks bear no weight at all but the timber frame does.

Panel homes uses the strongest, most permanent materials for the most important structural roles. Now that’s smart. Concrete – not pine to hold the roof up.

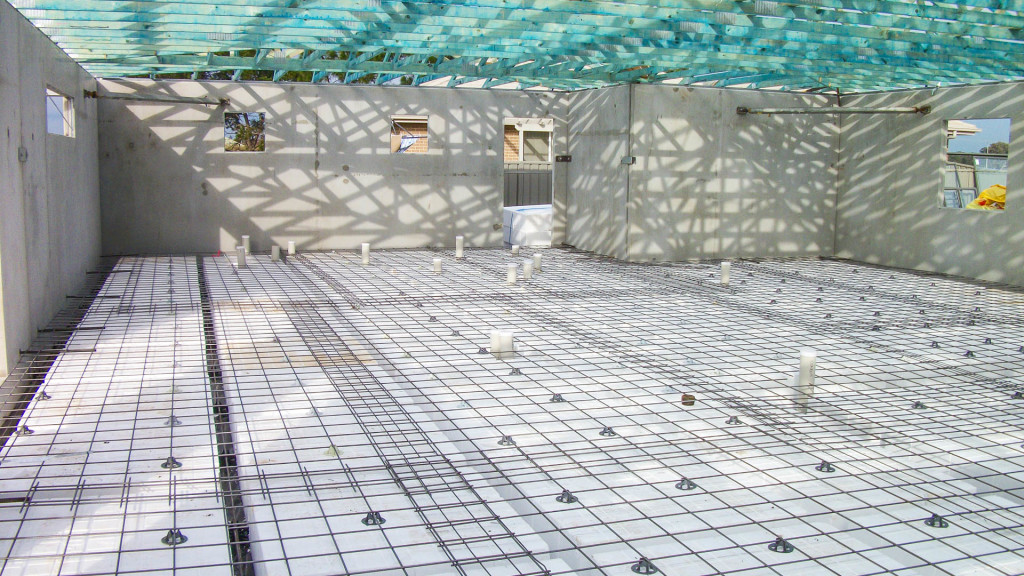

Days 5 and 6

Now that the roof is on, we can now remove any temporary bracing. Next, dig in the drainage plumbing and prepare for the slab to be poured. The walls are the form-work and the starter bars that are now threaded into the walls at slab height will bind the two elements together.

The slab is set with polyurethane panels to create the footings grid (sometimes called ‘waffle raft’) and the steel reinforcement is positioned.

Day 7

The slab is poured using a concrete pump.

Days 8 & 9

Now it’s time for all the internal wall frames including those for the lining of the external walls to be erected. The external walls maintain a cavity as you’d expect and the frames allow for lining with traditional materials. That’s right, your walls are plasterboard on the inside – not concrete.

Next the windows are fitted to the external walls where an integrated weather-tight sills has already been cast into the wall panel. The external door frames and doors are installed.

Day 10

Your home is now structurally complete, water tight and secure “Locked Up”. This is where the revolutionary process of building a precast home ends and traditional finishing techniques and materials continue. Now the processes of plumbing, wiring, lining, molding, painting and floor and window covering can take place. The project started from a completely square and true framework making framing and lining and floor tiling a breeze. The remainder of the project will usually take between 7 and 9 weeks.

10 Weeks – Move In

*These timings are indicative for a single story, 4 bedroom, standard design home on a level block.

That’s fast. In most cases, you’ll be moving in when a typical project home is just having it’s brickwork finished. It’s generally twice as as fast to build a panel home and it’s structural design life is far greater than conventional brick-veneer construction. So your new home will have a quick birth and a long life.

%

Resistance To Damp

%

Acoustic Mass

%

Thermal Benefits

%